5G Industrial Use Cases

5G Technologies Promise to Increase Product Innovations, Improve Performance, and Save Costs for the Industrial Segment

NEW INDUSTRIAL USE CASES WITH 5G TECHNOLOGY

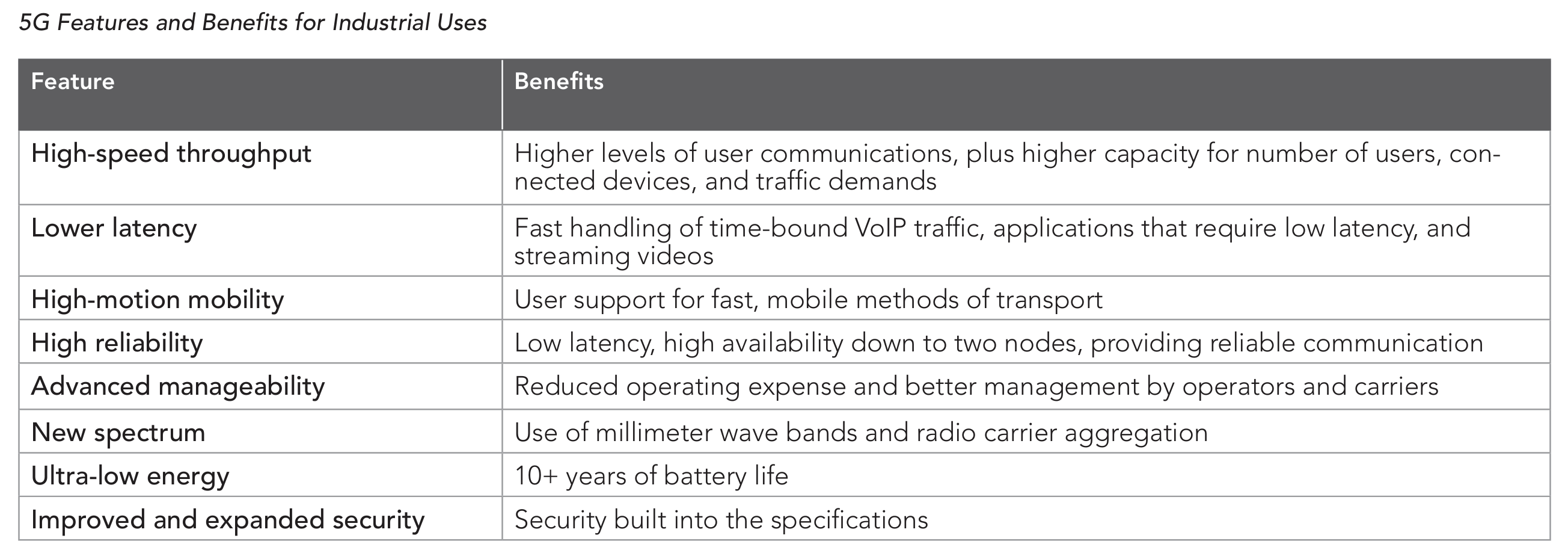

With this new wave of 5G features, including high-speed throughput, low latency, high reliability, and the other features outlined in the chart above, industrial equipment will be able to offer innovative technologies and services to support critical applications for a variety of use cases. Let’s look at three industrial use cases that can use 5G technologies to increase production, improve operations and management, and be more cost-effective.

5G Transforming the Manufacturing Floor

If you were to visit a manufacturing plant or factory, in many cases you will find that its equipment is at least 10 years old and based on older technology. Most of these machines are oper ating and communicating through cables connected to other equipment or the computer network. The first area that can easily benefit from the introduction of 5G wireless technology is the replacement of cabling with wireless communication. With 5G, the network communication speed will be just as fast or faster than the communication via cables. Further advantages will include faster equipment movement and reconfiguration, updates and installations without need for cable installation or upgrades, and a large savings in cabling costs. Additionally, re configuration of equipment within a facility can be completed much more rapidly without dealing with cable. As examples, think of updating a sewage treatment plant or updating a chemical processing system.

The next 5G benefit that manufacturing will see is that compa nies can vastly expand the sensors within their factories. 5G’s wireless capability, high-speed capacity, low latency, and avail ability will allow more data to be transmitted quickly and more frequently, providing more data to the edge cloud computing system within the plant to operate the equipment at optimal

performance or to easily make adjustments for different processing runs. With more equipment data, this will enable a predictive maintenance system to foresee failures or the need for repairs, as well as reduce unneeded maintenance or shutdowns.

5G Enabling Mobile Industrial Robots— Safe and Secure

5G technology will be a catalyst for driving advancements in mobile robots within the industrial segment (as well as other segments). With 5G wireless technology, robots will become more mobile, no longer tethered by cables or limited by the bandwidth of 4G wireless technology. Industrial robots will now be able to receive and send data via high-speed throughput, low latency, and broad data bandwidth to collaborate safely with humans and factories with expanded capabilities. Artificial intelligence and machine learning via the cloud using 5G will enable intelligence to navigate about facilities and people safely.

5G will advance robot capabilities through computer vision and sensors driven by 5G low-latency transfer of data to conduct safe mobile operational functions. Functional safety for robots will be strengthened through the use of real-time computer vision and sensors through 5G wireless.

5G Remote Monitoring and Control of Wind Farms

In Europe and the United States, wind farms are a significant com ponent of energy generation. Wind farms need to have remote monitoring and control to manage their windmills along windy coastlines or in rural lands. Bringing in 5G wireless communica tion enables energy companies to get more detailed wind-farm data faster, with lower latency, and over greater distances. The control automation and monitoring systems created by manu facturers will house 5G communications in the systems supplied to energy providers; this enables health monitoring of windmills, controlling and configuring remote systems with more data, and receiving rapid and prompt alarms when there are system issues, which all result in enhanced wind farm production, operation, and actionable data.

THE RESULT

5G wireless technology is coming to the industrial segment. 5G will bring advanced capabilities and innovation to the equipment, services, and performance of industrial equipment and operations that will be a catalyst to Industry 4.0. The new capabilities will transform how industrial and manufacturing equipment perform, their efficiencies, and the cost of operation—enabling new use cases that will change the way industries and business function, as well as the ways people work.

These three industrial use cases reveal just a fraction of the ways in which 5G will deliver innovation for advancing the next generation of industrial equipment and operations. As 5G rolls out, the industrial segment will see 5G usage expand across all components of control automation, manufacturing, logistics, robotics, and more.

To learn more about Wind River® and its product support of 5G innovations, visit our website or contact our sales inquiry desk.