Elevating Safety and Security: New Industrial Automation and Advanced Robotics Breakthroughs

Safety-Critical Industrial IoT Applications Require Real-Time Responsiveness and Security Embedded in Silicon

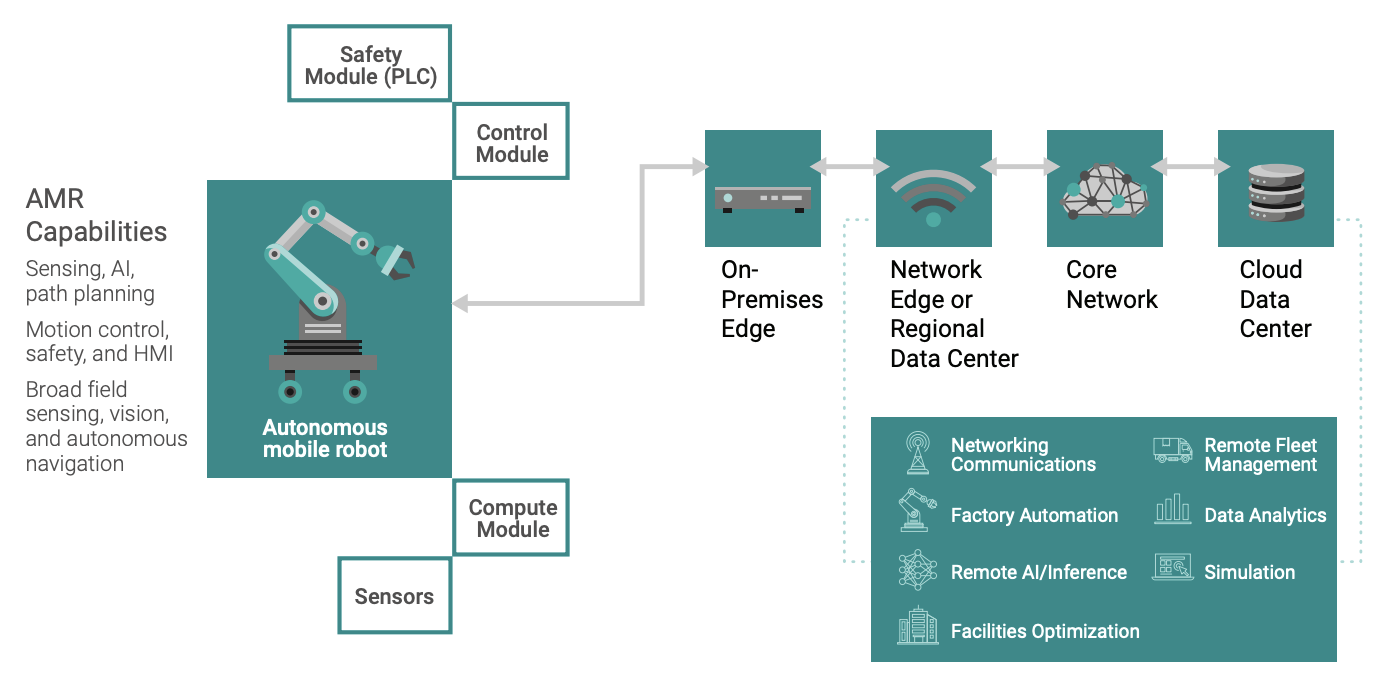

A host of technologies combine to enable the use of autonomous mobile robots, including AI, networking communication, simulation software, and data analysis. For example, 5G networking is a vital component of AMR adoption. The Capgemini Research Institute said in an article, “Realizing the Power and Promise of Industrial 5G,” “5G greatly enhances the range and field of operations for robots and autonomous machinery — far exceeding the capabilities of current connectivity technologies such as WiFi. This becomes even more critical as autonomous mobile robots or drones become a more mainstream part of manufacturing operations. It can also help to adjust production lines faster.”

Beyond AMRs, the future of automation will encompass other types of robots and industrial systems, including:

- Articulated robots: Robot arms capable of emulating the motions and actions of human arms have a wide array of uses in factories, warehouses, pharmaceutical facilities, and more.

- Automated guided vehicles (AGVs): AGVs can traverse predefined routes for delivering and moving different materials and objects within a facility.

- Humanoids: Robots with human-like appearance and characteristics can play a role in different scenarios, such as offering information services, guidance, and way-finding tasks.

- Cobots: Working side by side with humans, cobots can streamline many different types of tasks, such as assembling equipment, performing operations in research labs, and helping with quality-control testing.

- Hybrids: New classes of robots that blend the skills and capabilities of the types discussed in this section will perform specialized, complex tasks.

As robots and automated systems become more widely integrated in human environments, sharing workspaces and performing a diverse range of tasks, certifications for safety-critical operations and secure performance will be essential.

Proactive protections embedded in hardware work in concert with the Wind River capabilities listed in the following section. At present, VxWorks is the only RTOS that fully supports 3rd Gen Intel Xeon D-1700/D-2700 processors.

Wind River Safety and Security Highlights

Wind River safety and security highlights include:

- Extensive compliance support: VxWorks safety certifications and compliance listings cover DO-178C, IEC 61508, ISO 26262, ARINC 653, POSIX®, and FACE™. Standards conformance and safety certification evidence has been demonstrated and documented on commercial off-the-shelf (COTS) systems.

- Four decades of proven, mission-critical performance capabilities: Wind River has a long and storied history working on some of the most challenging and safetycritical applications around the world.

- Open Container Initiative (OCI) container support: Wind River has engineered OCI container support into the latest version of VxWorks, which is now the only RTOS that supports deployment of applications using containers. Developers can use familiar languages, tools, and technologies to build and deploy solutions securely, enabling intelligent automation systems. Container technology can be used to perform rapid application updates and patches in response to newly detected vulnerabilities.

- Vulnerability notices: Wind River maintains continuous threat monitoring, rapid assessment and prioritization, and prompt customer notifications with advice on remediation. System threats in IIoT deployments can be quickly remedied before threats cause issues. Security patches are readily available and potential risks are identified through a searchable database linked to MITRE’s list of Common Vulnerabilities and Exposures (CVEs).

- Cyber testing: Wind River Simics® lets developers run extensive cyber tests and detect system vulnerabilities, using modern simulation and automation technologies, without risking exposure to the actual hardware or software in IIoT and robotics systems under development.

- Built-in security: The integral security features built into VxWorks include a hardened kernel, secure communication, and data protection. VxWorks functions on multiple levels using a framework based on the CIA triad. Throughout the full range of system operations — from system startup through shutdown procedures — VxWorks provides access to features that let system architects integrate the appropriate level of security for applications and shut down potential risk vectors.

Bedrock Security Is a Must for Businesses Deploying Robotics Systems

An equally important aspect to the deployment of industrial automation and robotics systems is security against intrusion and protection of system integrity. Autonomous vehicle operations in cities, drones moving through public airspace, robots in factories and warehouses, robots used for physical therapy or in hospital settings — all of these use cases have a potential for disastrous outcomes if systems are breached.

Intel and Wind River are leaders in hardware and software security innovation, with technologies that are layered and interoperable to anticipate threat vectors and guard against breaches.

Suzy Greenberg, vice president, Intel Product Assurance and Security, said, “The security threat landscape continues to evolve, becoming more sophisticated and challenging for organizations to defend against. Today, more than ever, companies are demanding assurance capabilities and hardware-enhanced security solutions that help protect the entire compute stack. Intel is in a unique position to deliver these innovations on behalf of our customers.”²

Software and Hardware Interoperating for Maximum Security and Safety

Any vulnerable point in an IIoT system — whether a single device without sufficient protection or a software program that is unguarded — can put the entire platform at risk. Maximum security is achieved in trustworthy systems built on a foundation with tight interoperability between hardware components and system software. This approach is central to the latest generation of IIoT solutions built on Intel hardware platforms running VxWorks in a Helix Platform environment.

Helix Platform — a component of Studio — unifies operating environments by supporting legacy applications and modern applications within a single virtualized environment that can be partitioned to avoid security intrusions into sensitive applications. Providing a single-pane-of-glass view into complex heterogeneous cloud platforms, on-premises equipment, or hybrid environments, Helix Platform offers an invaluable management tool that can drive multiple hypervisors.

Developers building industrial automation and robotics systems can save time and effort by relying on certifications of key components to satisfy industry requirements. Intel Xeon D-1700/D-2700 processors provide a clear pathway for meeting AC-20 193 and AMC-20 193 objectives for demonstrating effective, safety-aligned multi-core processor usage. Intel safety evidence packages are also available for IEC 61508.

VxWorks has also earned an outstanding reputation in the IIoT sector and achieved certifications and evidence packages supporting DO-178C, IEC 61508, IEC 62304, and ISO 26262 safety standards. VxWorks delivers multi-core and multiprocessor support and can run on 32-bit and 64-bit multi-core processors that are based on Intel, Arm, Power, and RISC-V architectures.

Intel, Wind River, and fellow ecosystem partners continue to acquire certification evidence packages and to meet emerging industry standards. These certifications and evidence packages simplify developer efforts to create safety-critical IIoT and advanced robotics solution stacks for the latest Intel processors and Wind River software components.

Additional Resources

To explore the ways in which VxWorks provides RTOS capabilities for embedded systems, connect to VxWorks: Redefining the Role of the RTOS and download the free ebook on this topic.

To learn more about the safety-critical applications supported by Intel Xeon D-1700/D-2700 processors, visit this page.

To learn more about certification of safety-critical applications, visit VxWorks Safety Platforms.

References

- Autonomous Mobile Robots, Intel, http://www.intel.com/content/www/us/en/robotics/autonomous-mobile-robots/overview.html

- Intel Study: Secure Systems Start with Hardware. Intel Newsroom. April 2022. www.intel.com/content/www/us/en/newsroom/news/study-secure-systems-start-hardware.html

- Cosgriff, Barbara. The Art of Defense: Mitigating Cyber Exposure with Threat Modeling. Forbes. May 2022. www.cryptooverwrite.coin.dnsalias.com/sites/windriver/2022/05/06/the-art-of-defense-mitigating-cyber-exposure-with-threat-modeling

- https://www.forbes.com/sites/windriver/2022/03/01/ai-robotics-and-ethics-harnessing-the-power-of-intelligent-machines-to-benefit-humans/?sh=650dc60d76be