Building Real-Time Avionics Systems Optimized for Intel Multi-core Processors

High-Performance Hardware and Software Primed for Mission-Critical Operations

Solutions Forged in Silicon for Delivering Certified Software Reliability

Building solid, reliable avionics systems requires a foundation that supports emerging hardware architectures and next-generation processor technology.

Silicon designed with latest-security advances embedded and with fail-safe component design is an important adjunct to an RTOS ready to meet the challenge of the extreme conditions, predictable behavior, and lightning-quick determinism necessary for aerospace and defense applications.

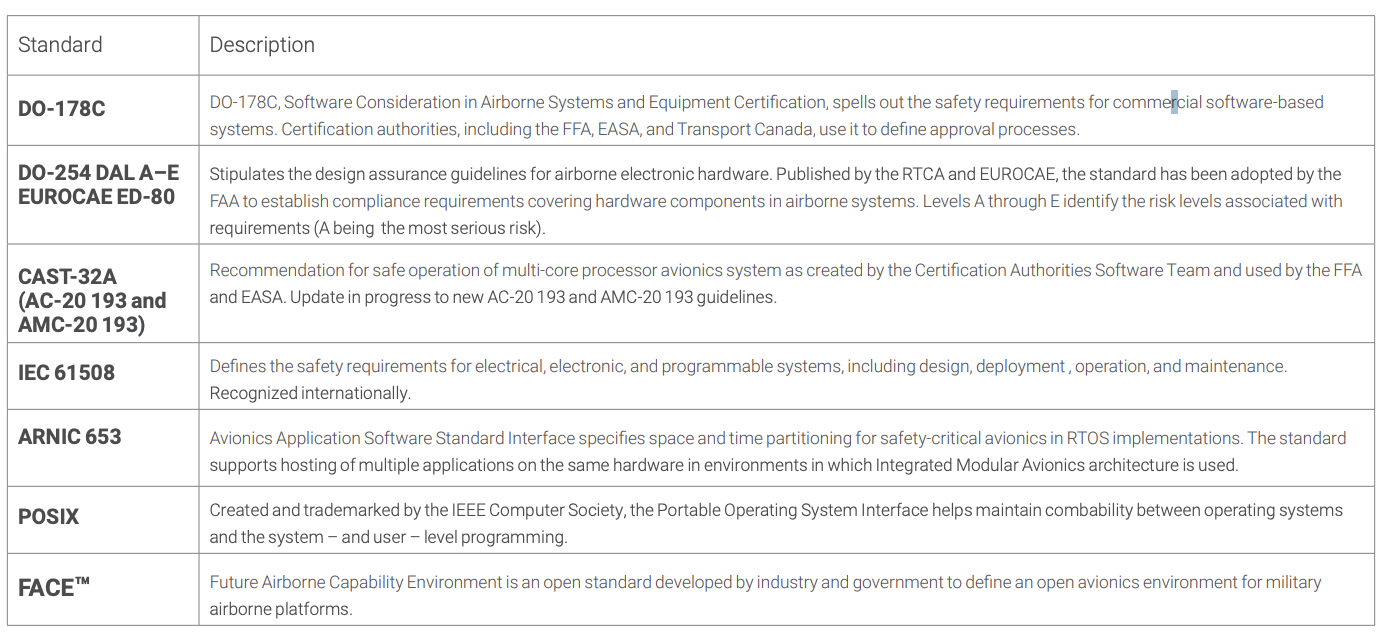

The Growing Matrix of Standards

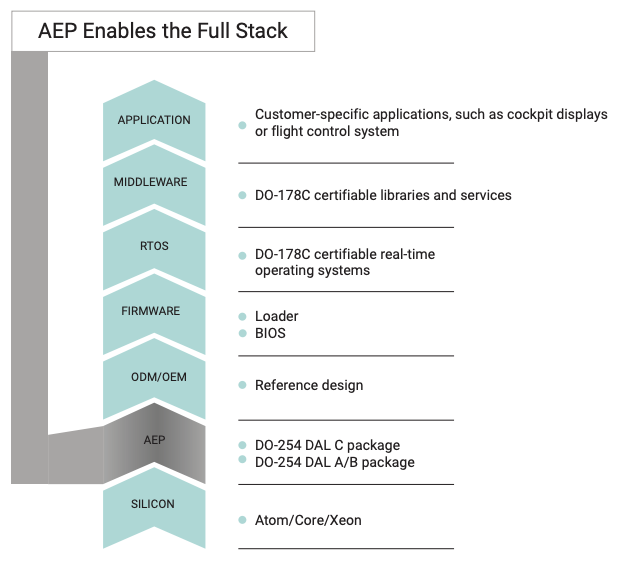

Avionics system designers are, of necessity, becoming accustomed to the interlocking matrix of complex requirements that must be met to earn airworthiness certification. A recommended path for navigating these requirements is to use building blocks, both hardware and software, that have obtained the core certifications and simplify the process of building systems that comply with required mandates.

The following table lists the key standards and requirements that are predominant in the commercial and military avionics sectors.

Wind River Intelligent Edge Software for Safety-Critical Avionics

Wind River delivers top-notch software, technologies, and tools to streamline the certification process, ensure safe operation if faults occur in the avionics system. Also, Wind River provides tools to develop and test the software using advanced simulations prior to installing a solution in an aircraft, expose cybersecurity vulnerabilities, and operate safely and efficiently in a highly virtualized software-defined environment.

VxWorks, the Gold Standard RTOS for Avionics Uses

VxWorks, a part of Wind River Studio, has been deployed widely in environments where demanding conditions and real-time responsiveness are vital to the success of the mission. VxWorks meets an extensive range of safety-critical application requirements, giving technology developers a streamlined means to become certified for DO-178C, ED-12C, EN 50128, v 61508, ISO 26262, and IEC 62304. VxWorks 653 is expressly designed for avionics solutions, consolidating and orchestrating workloads upon a proven Integrated Modular Avionics (IMA) platform.

VxWorks is the only RTOS that supports both embedded 11th Gen Intel Core processors and embedded Intel Xeon D processors.

For the most demanding avionics applications, the Wind River VxWorks 653 Platform incorporates multi-level safety using a multi-core scheduler supporting hardware virtualization assist operations. On an open virtualization platform, VxWorks 653 uses robust time and space partitioning on multi-core processor platforms, including those powered by Arm®, Intel, and PowerPC processors. This technology has been widely adopted in aerospace and defense applications. More than 360 customers in over 600 safety programs have incorporated this technology, deployed and proven in more than 100 civilian and military aircraft.

Standardization Drives Design Interoperability

Across both the commercial and military avionics sectors, the need for establishing standards for systems and aligning the ecosystem around agreed-upon guidelines reduces uncertainties in solution reliability, safety, and agility.

Military Embedded Systems Editorial Director John McHale explained the benefits in this way: “CAAS [Common Avionics Architecture Systems] uses common hardware components to lower lifecycle costs and enable more effective upgrades. FACE™ (Future Airborne Capability Environment) does this through software. Both initiatives are effective because what they do — enabling commonality and reuse across multiple platforms through standard interfaces — makes economic sense.”¹ Rather than being built on an entirely new standards platform, FACE amplifies and extends POSIX and ARINC 653 standards.

For FACE, a certificate of conformance is achieved by testing solutions against the standardized API sets. VxWorks 653 Safety Base Profile has earned FACE 2.1 conformance and was the first product to attain FACE certification. Wind River Helix™ Virtualization Platform has gained FACE 3.0 conformance. Wind River Linux conforms with the FACE 3.0 General Purpose Profile and is the only version of Linux to be certified for the FACE standard.²