CERTIFY FASTER WITH SIMULATION

The Virtues of Virtual Platforms (cont’d.)

Moreover, virtual platforms provide software debugging and analysis features that are simply not possible to implement on physical hardware. Unlike a traditional test run on hardware, in which you lose time rerunning the software and hoping to spot the bug, Simics enables you to run time in reverse to locate the precise breakpoint. It’s easy to see a problem after it has occurred, but what if you could figure out its cause before it occurs? Simics’ reverse execution enables you to do just that — in effect, to go back in time to find the source of a bug and fix it on the spot.

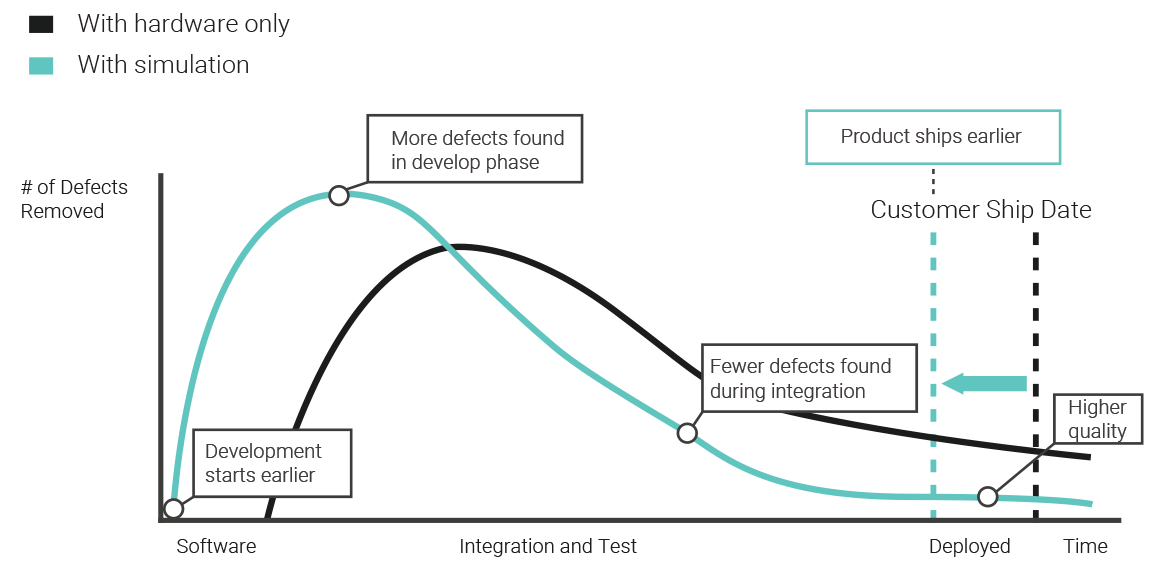

Developing on Simics has been proven to enhance developer team collaboration, reduce development time and costs, and accelerate time-to-market while ensuring the quality and performance of the end product. Development can begin earlier, more defects are found and removed during development, and quality is achieved sooner.

Figure 1. With a virtual platform, more defects are discovered and removed earlier in the cycle. Development begins earlier and the software achieves the required quality sooner.

Conclusion

Using Simics reduces total certification costs as well as performance and program risks, and it helps ensure timely delivery of a quality product. The ability to detect and fix defects during development rather than during testing makes the entire process far more efficient. And you’re not reliant on test hardware, which can be expensive and limited in availability.

Ultimately, for safety certification, final software must be tested on final hardware — you have to be able to “test what you fly and fly what you test.” Simics is not a substitute for genuine hardware certification. What it can do, however, is ensure that your software is ready to meet the final test requirements — and in the process save time, cut costs, and reduce risks.