ECU Consolidation in Tomorrow’s Connected and Autonomous Car

Delivering State-of-the-Art Functionality While Keeping Software Complexities Under Control with Minimal Impact on the Testing Process

THE SOLUTION

No single technology partner can resolve the business challenges of ECU consoli dation, but the Wind River® perspective is that a technical solution to consolidation will accelerate the resolution of business challenges. Therefore, we have dedicated our resources to that effort.

We can certainly learn from other markets that have already solved similar technical and business challenges. A great example is the aerospace industry, where integrated avionics systems have been launched successfully. The technical solution of consolidation—and the clear definition of roles such as platform provider, application provider, and software integrator—has helped to overcome the business challenges. With its long record of both automotive and avionics experience, Wind River is in a position to combine the expertise of these markets.

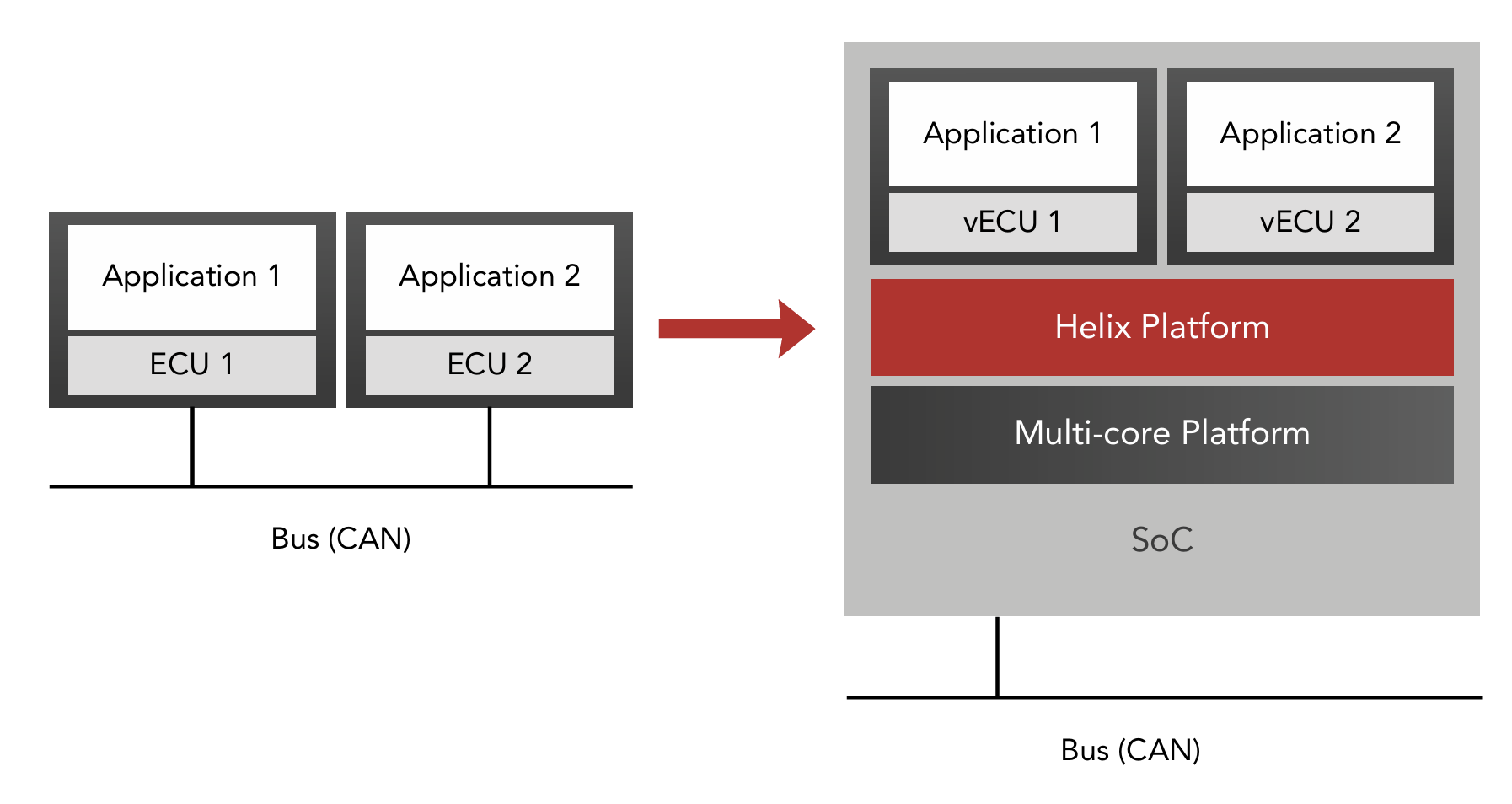

Wind River and other vendors have worked on a new approach that virtualizes the ECU. A virtualization layer is used to run multiple ECU operating systems simultaneously on a single processor, as shown below:

This virtualization model makes it possible to choose the appropriate solution for each application, run non-critical and critical systems side by side, and provide clear fault isolation. A level of determinism is also necessary to run mixed-criticality systems side by side and bring advanced driver assist system (ADAS) features into the vehicle. Aerospace and defense manufacturers have validated that, with proper levels of determinism and time and space partitioning, they can update hardware and software— and update hardware independently of the middleware and application layers, because they can all operate on different time cycles or life cycles. That means that manufacturers can drive more speed in the development cycle and deployment while reducing both the cost and complexity inside the actual hardware.

Wind River Helix Virtualization Platform

Wind River Helix™ Virtualization Platform is a commercial off-the shelf (COTS) product for delivering an automotive solution that enables application consolidation with different levels of safety criticality on a single edge compute platform. This virtualization platform supports mixed-criticality OSes, providing the ability to run safety-critical and general-purpose applications side by side. Whether the main concern is a real-time operating system (RTOS), Linux, safety, security, latency, determinism, criticality, or a combination of these, Helix Platform offers the flexibility of choice, allowing consolidation of all types of functions into a single platform—today and into the future.

Helix Platform is developed from the Wind River market-leading RTOS product line VxWorks®, which has a rich pedigree of single and multi-core development and has been proven in more than 2 billion devices worldwide. VxWorks has been trusted by more than 9,000 companies and has been chosen as the RTOS to go to Mars with NASA for nearly 25 years, most recently in the 2018 InSight robotic lander. In its nearly 40-year history, VxWorks has amassed an extensive portfolio of safety certification experience with more than 550 safety certification programs in more than 90 civilian and military aircraft, and more than 350 customers using the VxWorks safety platform. VxWorks has also been certified to meet ISO 26262 automotive functional safety requirements. Its modular, open architecture employs robust partitioning, eliminating the need to retest and recertify the entire platform when a change is made to one of the partitions, and reducing total cost of-ownership (TCO). New partitions can also easily be added to the device without retesting the entire system.

The Helix Platform hypervisor is OS-agnostic, which means it is capable of running any operating system, unmodified, inside a virtual machine (VM). Support for unmodified guest OSes eases portability for legacy applications mixed with modern, standards based applications and operating systems. Guest OS support includes the leading embedded RTOS, VxWorks; the leading commercial embedded Linux operating system, Wind River Linux (and other Linux operating systems); Ubuntu; ROS; and other operating systems. Helix Platform also supports advanced separation technology, allowing legacy code reuse and the ability to utilize open source for flexibility.

Wind River Linux

Wind River Linux is the embedded operating system of choice for IIoT software developers who want a combination of open source f lexibility, commercial grade reliability, and support to help minimize the total cost of ownership. Wind River Linux delivers vital components for the productization and commercialization of any IoT device. Within a Helix Platform workload consolidation solution, a Wind River Linux VM can be established to run Linux applications.

Wind River Development Tools

To create a workload consolidation solution for your specific manufacturing components and needs, Wind River provides powerful and time-saving development tools. Wind River Simics® is a simulation platform that can simulate any compute mode, chip to system. Along with its capabilities for scripting, debugging, inspection, and fault injection, Simics enables you to define, develop, and integrate your systems without the constraints of physical target hardware. It provides the access, automation, and collaboration tools required for agile development practices. Wind River Diab Compiler helps boost application performance; reduce memory footprint; and produce high-quality, standards-compliant object code for embedded systems. Diab Compiler is also ISO 26262–certified as a software tool for safety-related development.

THE RESULT

Using the Helix Platform and its hypervisor together with VxWorks, Wind River Linux, and Wind River development tools, an ECU consolidation solution can be applied in the automotive industry. Development, testing, and security teams can take a closer look at the underlying technology of this new approach—and at the possibilities for improving the efficiency of new automobiles, the safety and security of future automobiles, the satisfaction and brand loyalty of consumers, and the bottom-line profitability of the business.

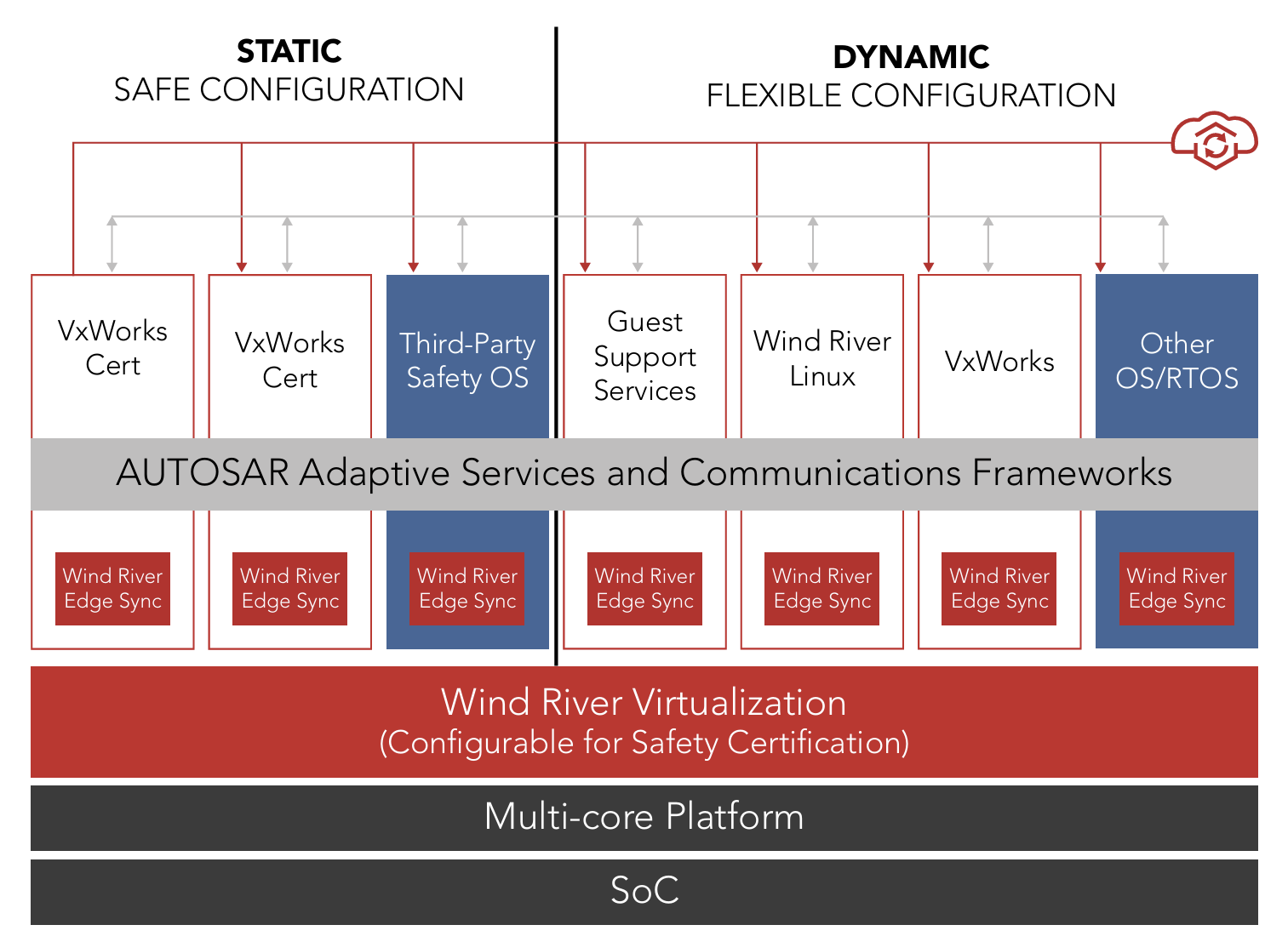

A typical system configuration, as an example, is shown below: